All concentrating solar power (CSP) technologies use a mirror configuration to concentrate the sun’s light energy onto a receiver and convert it into heat. The heat can then be used to create steam to drive a turbine to produce electrical power or used as industrial process heat.

Concentrating solar power plants can integrate thermal energy storage systems to use to generate electricity during cloudy periods or for hours after sunset or before sunrise.This ability to store solar energy makes concentrating solar power a flexible and dispatchable source of renewable energy.

CSP systems can be also combined with combined cycle power plants resulting in hybrid power plants which provide high-value, dispatchable power. They can also be integrated into existing thermal-fired power plants that use a power block like CSP; such as coal, natural gas, biofuel or geothermal plants.

CSP plants can also use fossil fuel to supplement the solar output during periods of low solar radiation. In that case, a natural gas-fired heat or a gas steam boiler/reheater is used.

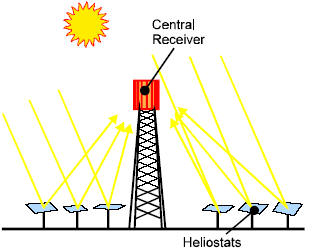

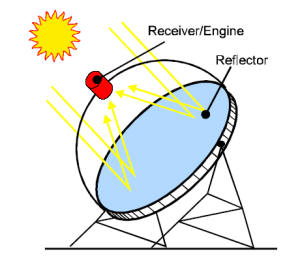

There are four types of CSP technologies, with the earliest in use being trough, and the fastest growing as of 2017 being tower. For each of these, there are various design variations or different configurations, depending on whether thermal energy storage is included, and what methods are used to store solar thermally.

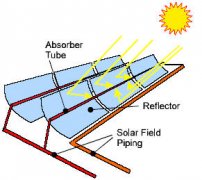

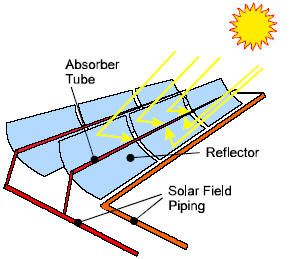

Parabolic Trough Systems:

In a parabolic trough CSP system, the sun’s energy is concentrated by parabolically curved, trough-shaped reflectors onto a receiver pipe running along about a meter above the curved surface of the mirrors. The temperature of the heat transfer fluid flowing through the pipe, usually thermal oil, is increased from 293ºC to 393ºC, and the heat energy is then used to generate electricity in a conventional steam generator.

A collector field comprises multiple parabolic trough-shaped mirrors in parallel rows aligned to enable single-axis trough-shaped mirrors to track the sun from east to west during the day to ensure that the sun is continuously focused on the receiver pipes. As of 2018, 90% of the CSP in commercial operation is trough.